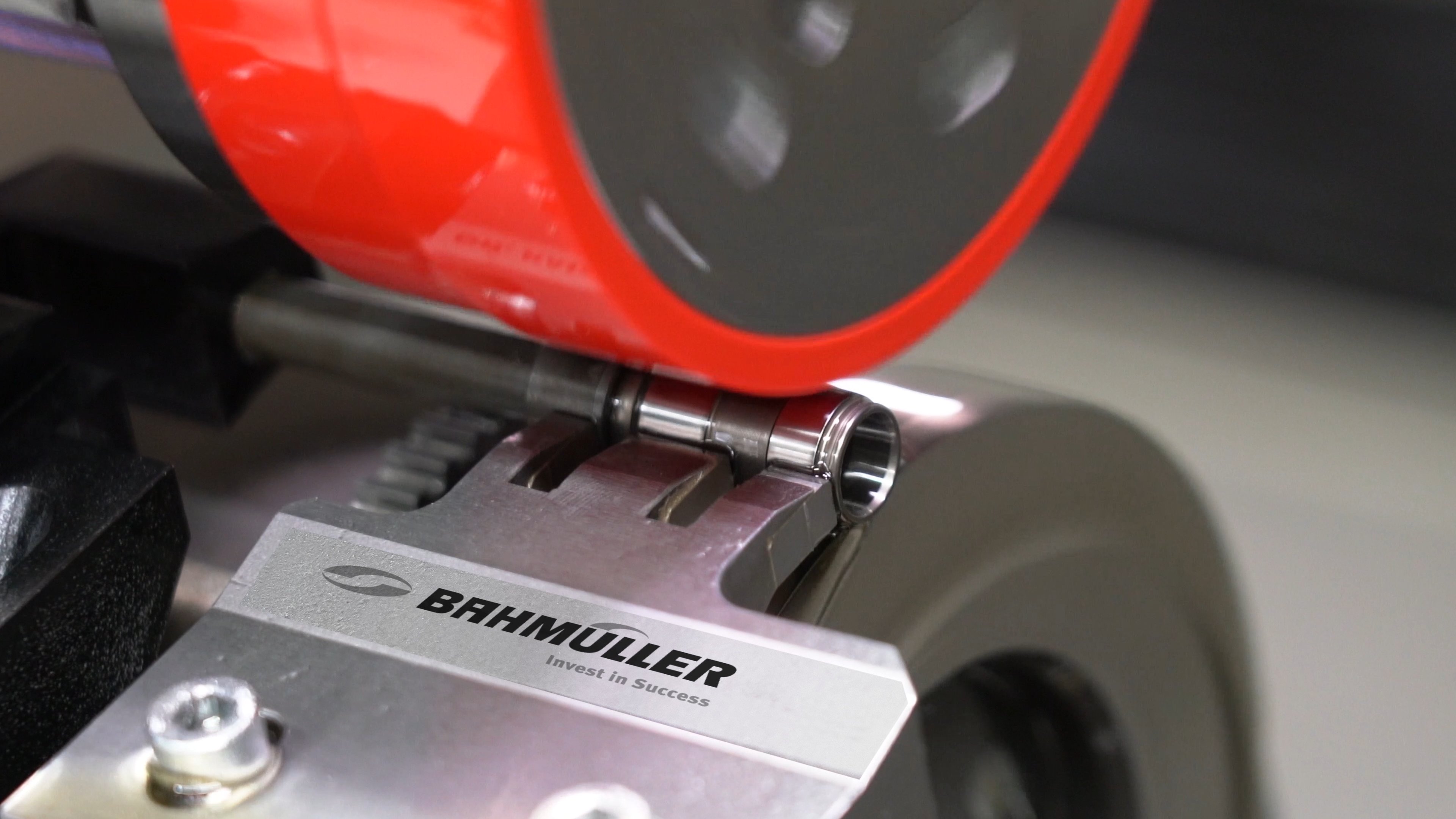

LASH ADJUSTER| How to reduce 30% costs per piece by using latest grinding technologies

Even for workpieces produced in hundreds of millions of pieces, dramatic efficiency options are possible.

The following BAHMÜLLER success story shows how!

With a unique dual-station-machine, an innovative clamping concept and optimized grinding technology, we do achieve 3 seconds output – fully automated and under real 24/7 production conditions.

The dedicated technology was developed, tested and approved in BAHMÜLLER´s TechCenter. Integrated gaging with auto-correction is available.

In addition to the very challenging cycle time, the innovative solution also provides excellent workpiece quality with roundness values inside the ground bore, well below one micrometer (forty millions of an inch). BAHMÜLLER is even taking care about common concerns of typical burrs generated by cross holes.

Europe / English (Language)

Europe / English (Language)